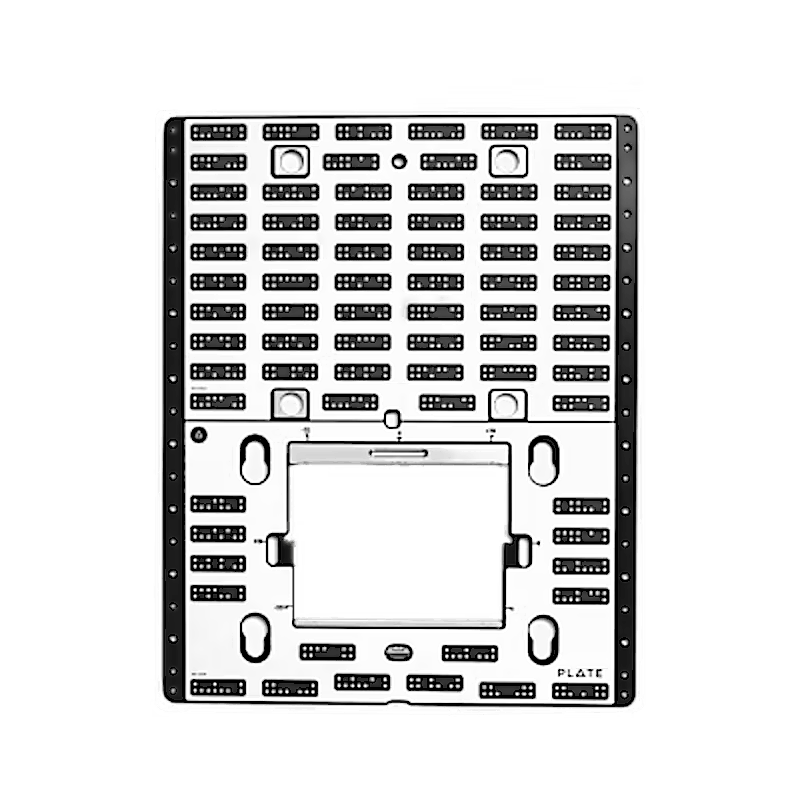

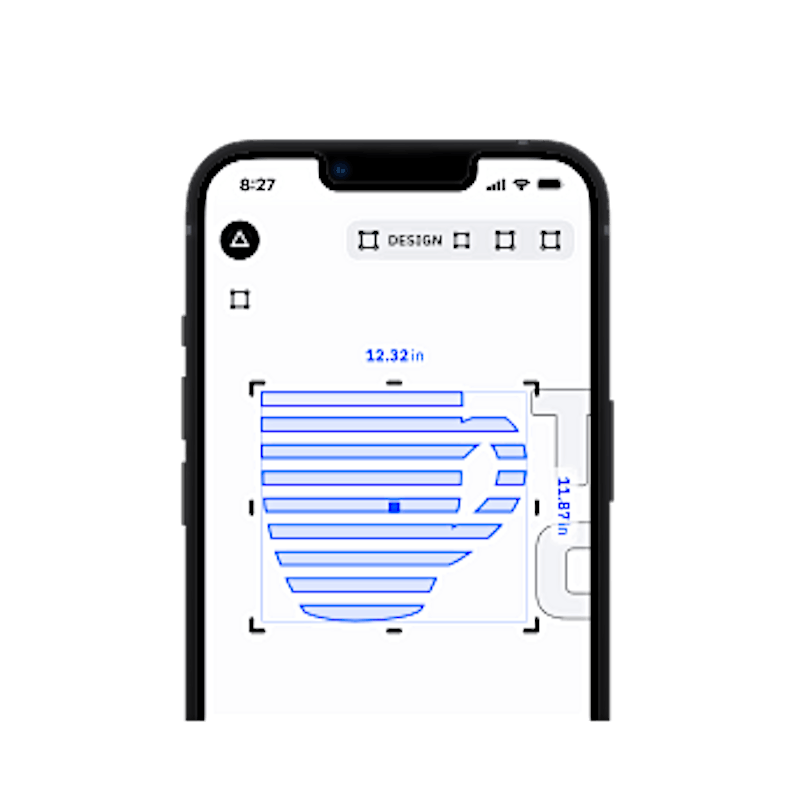

Improving The Way You Work

See how businesses are taking advantage of digitally-aided cutting without the cost and complexity of traditional CNC machines.

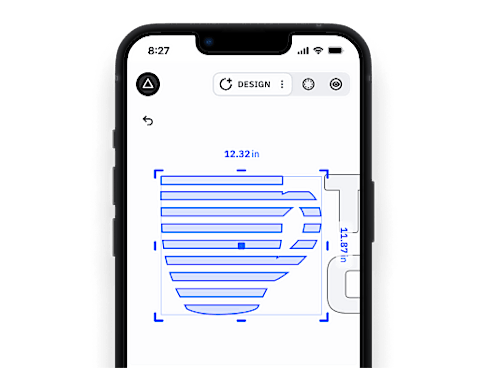

Fine Furniture

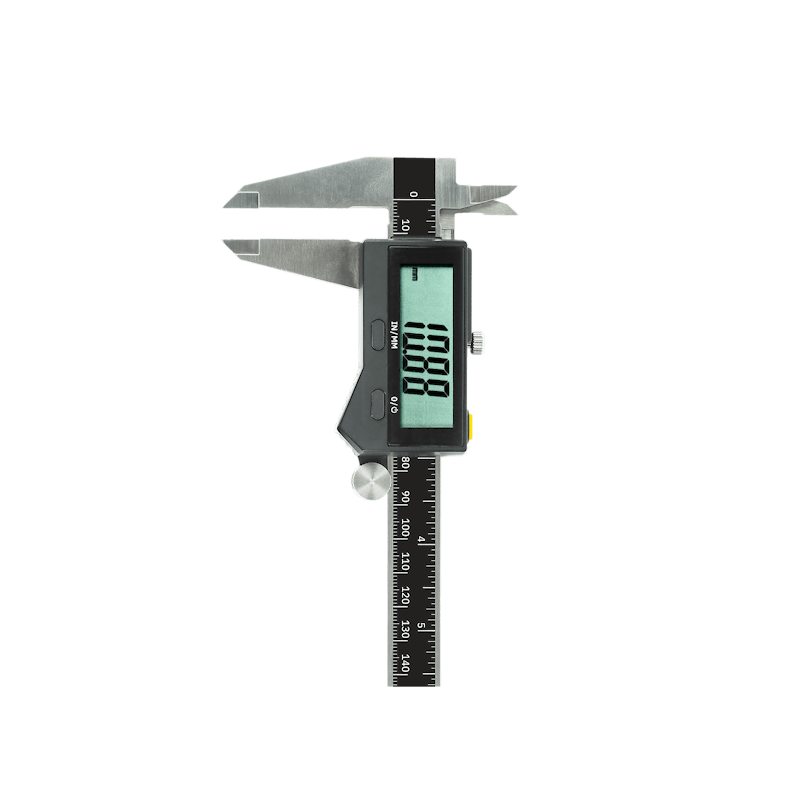

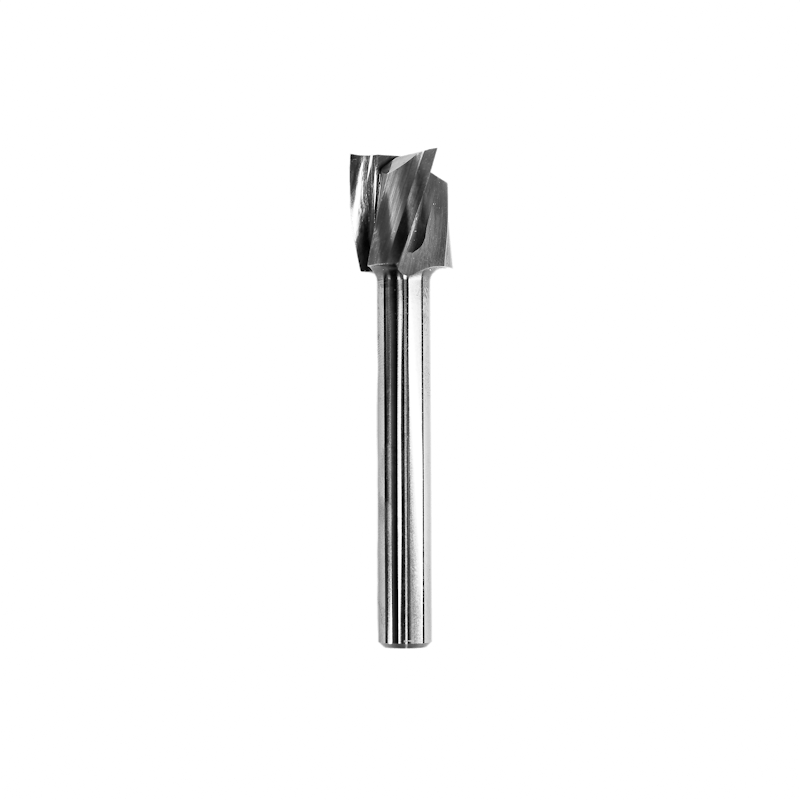

Add sophisticated elements and handcrafted details to solid wood projects and custom furniture. Build templates, engrave, and cut unique joinery with ease and precision.

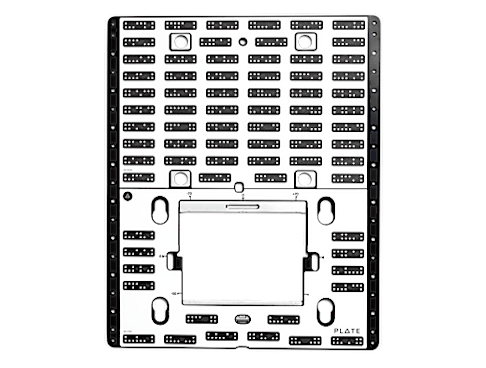

Cabinetry

Work efficiently and quickly with solid wood, plywood, Corian and other sheet materials. Inlay hardware, cut mortises for door hinges, and make on-the-fly adjustments, both onsite and in your workshop.

Flooring

Perform routine operations like Dutchman patches, repairs and hardware installations all the way through to fully custom inlays.

Bring CNC precision to the job site and tackle any size of project.

Sign Making

Bring your customers’ dreams to life by creating personalized signage, large or small. Cut with digital precision in a variety of common materials, like wood, plastics, laminates. Install hardware or mounting details without hassle.

Manufacturing

Give your engineers the freedom to create functional prototypes and precision fixtures to expedite product development. Save time iterating and making adjustments on the fly—all in-house without any outsourcing.

Education

Introduce your students to the future of computer-assisted manufacturing and CNC technology with accessible, safe and intuitive tools.

Expose students to the core concepts of digital fabrication in a more engaging, more hands-on and safer environment resulting in faster acquisition of concepts and lasting retention.

Everything You Need to Get to Work

Get the most out of Origin with access to project plans, learning resources, design support services and more

![[object Object]](https://images.prismic.io/shapertools/baa835fd-721f-4d18-9658-12ec520fefb7_KSA_Trace_Studio-449-Edit.jpeg?auto=compress,format&rect=0,1374,5688,1750&w=1528&h=470)

![[object Object],[object Object]](https://images.prismic.io/shapertools/282d6f93-ccd2-434f-923f-eed63824d70a_Placeholder_Hub_Nav.png?auto=compress,format&rect=0,61,1529,470&w=1528&h=470)

![[object Object],[object Object]](https://images.prismic.io/shapertools/8f1a60d5-4775-4c41-80e5-81a107fa0b98_Sessions.jpg?auto=compress,format&rect=0,538,3000,923&w=1528&h=470)